EQUIPMENT

Equipment

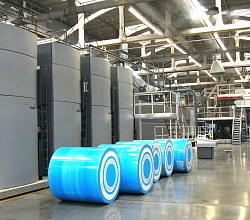

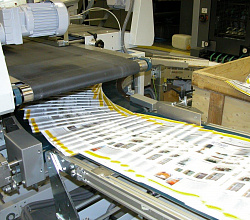

The Joint Stock Company Polygraphic Complex “Pushkinskaya Ploshchad” has the largest base of high-speed offset web presses in Russia, produced by HEIDELBERG & GOSS companies.

Our base of the offset web presses consists of 11 modern high-performance presses printing at the speeds of up to 90 000 copies per hour.

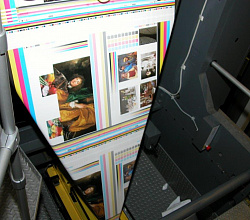

The printing presses allow to produce the finished products amounted of 4 to 48 A4 pages, 4 to 24 A3 pages, or 96 semi-finished products of A5 size per one cycle of the printing press with high performance (see the equipment capabilities).

The base of the offset web presses comprises six high-speed presses HEIDELBERG/GOSS SUNDAY and six presses HEIDELBERG/GOSS M600:

- HEIDELBERG/GOSS SUNDAY-4000/48pp – 4 offset printing presses with performance of up to 90 000 copies/hour.

- HEIDELBERG/GOSS SUNDAY-2000 (Duplex)/24pp – 2 offset printing presses with performance of up to 52 000 copies/hour.

- HEIDELBERG/GOSS M-600 (Duplex) /16рр – 2 offset printing presses with performance of up to 70 000 copies/hour, with capability of duplex operation.

- HEIDELBERG/GOSS M-600 24/16рр – 4 offset printing presses with performance of up to 45 000 copies/hour.

All web presses are duplicated, and this significantly increases the reliability of printing the magazines exactly on time.

Our important advantage is that the base of the web presses is optimally matched for cutoff lengths (from 578 to 630 mm), we are ready to provide the customers with a wide range of publications in various formats with the minimum paper process waste, which reduces the cost of the final run.

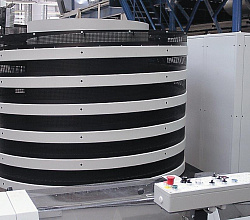

All web presses have a maximum level of automation and are equipped with multi-functional complexes of postprint process RIMA-System, that is, from each web press one can receive the finished publication: fastened with glue or metal staple, trimmed on three sides, highly artistic and high-quality printed magazines. Our equipment and technologies allow us to produce the magazines with different paper grades, as well as to work with a large range of paper weight from 35 to 150 g/m2.

The Joint Stock Company Polygraphic Complex “Pushkinskaya Ploshchad” has two offset sheet presses manufactured by HEIDELBERG:

- HEIDELBERG XL 105-6+L- six-color offset sheet press with coating unit with performance of 18 000 sheets/hour of 1050х750 mm size.

- HEIDELBERG XL 105-5+L- five-color offset sheet press with coating unit with performance of 18 000 sheets/hour of 1050х750 mm size.

- HEIDELBERG CD 102-LYX – offset press for applying various UV varnishes on the printed sheets, with performance of up to 13 000 sheets/hour.

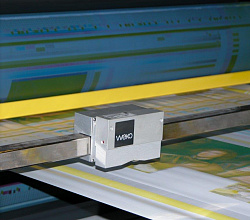

The sheet presses HEIDELBERG Speedmaster, models XL 105 and CD 102 are one of the most reliable and advanced in the world, they are equipped with the latest printing presses control systems in the printing industry. Automatic register control, control of color on impression and ink feed, as well as many other automation tools considerably optimize our production.

Modern publishers of periodicals are imposing ever greater demands on the print quality and variety of finishing. Any fantasies of the designers working on the artistic appearance of the publications and advertisers running promotional campaigns of the editions can be implemented with the equipment of the Complex. The printing house has a solid base of the finishing equipment and bookbinding equipment.

The bookbinding equipment base consists of 10 lines of SSTL (saddle-stitching-trimming lines) manufactured by HEIDELBERG, and 4 lines of GPBL (glue-perfect binding lines) manufactured by KOLBUS.

Ten high-performance SSTL lines:

HEIDELBERG STITCHMASTER ST-450 (five lines), ST-400 (three lines) and ST-300 (two lines) , with performance of 16 000, 14 000 and 12 000 copies/hour, and the number of feeders – 4, 6, 8 to obtain any needed amount of pages in publication.

Four lines of glue-perfect binding GPBL:

KOLBUS KM-411 (two high-performance GPBL lines with performance of up to 16 000 copies/hour), and KOLBUS KM-472 (two high-performance glue-perfect binding lines with performance of up to 8 000 copies/hour). Two glue-perfect binding lines have the options of two-ups cutting, which allows us to produce the materials of A5 and smaller sizes with high performance, which also makes our production flexible to any publication formats.

Our base also comprises six flowlines of copy-by-copy packing of the finished magazines in various kinds of films:

- SITMA C80/750, (2 copy-by-copy packing lines, adapted to inserting and gluing of sachet and various advertising products in a magazine)

- BUHRS 2000 (MTR) (2 copy-by-copy packing lines, adapted to inserting and gluing of sachet and various advertising products in a magazine)

- Kallfass Servo 500, (2 copy-by-copy packing lines of the magazines with a complex form and non-standard sizes.)

For different types of finishing the printed products, our company has a large number of modern ancillary equipment:

- Five folders Heidelberg TD-82, TD-78 and Ti-66;

- Four flat cutters,

- Over twenty speed lines of packing the parcels of the finished products into the heat-shrink film.

The prepress printing shop has the necessary number of the latest equipment for non-stop production, providing the control and stable quality of the issued printed products - at all stages of production.

The printout devices section is represented by the following:

- ATHE APPARTUS OF DIRECT EXPOSURE OF PLATES CtP MAGNUS VLF MCU

- CtP TRENDSETTER 800 III QUANTUM

- Color proof complex:

- Modern color proof complex GMG ColorProof

- The option of the printed color proofs ProofControl

- Large-format printer Epson SureColor SC-P7000, size А1, prompt color stabilization, covering 98% of Pantone colors

- Modern color proof complex GMG ColorProof

- Modern test and measuring equipment: scanning spectrophotometers, spectrodensitometers, software for analysis, calibration, profile-building and process optimization.